Core Advantages

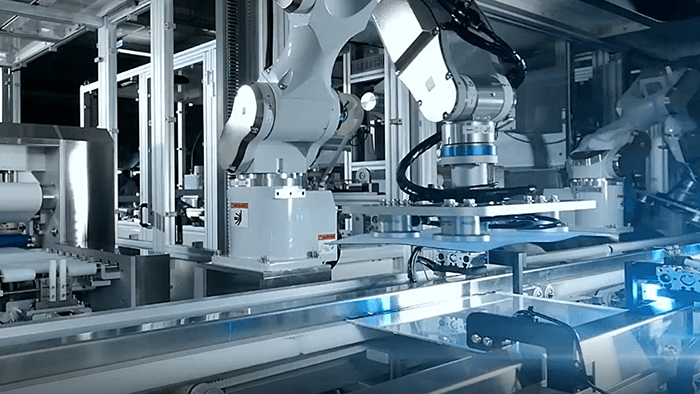

Global Precision Stamping Solution Strategic Partner.

-

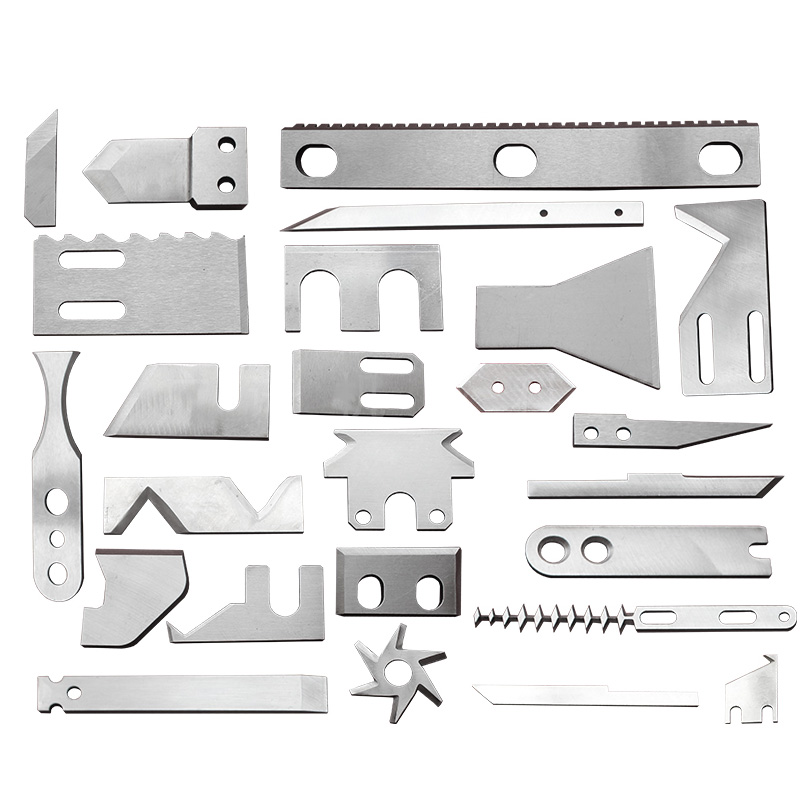

Ultra Precision Machining Capability

Tungsten Steel Punching Needle/Punch: Hardness Hrc90+, Tolerance ± 0.002mm, Service Life 3-5 Times Longer Than Ordinary Punch.

Multi Station Progressive Die: Supports Continuous Punching, Deep Drawing, And Material Cutting Composite Processes, Suitable For High-Precision Requirements In The Automotive/Electronic Field.

Customization Of Non-Standard Irregular Punch Needles: Covering Over 2000 Models Including A-Type Punch, T-Type Punch, Liner, Die, Etc., Supporting Mirror Processing (Smoothness Ra0.01 Μ M). -

-

-

-

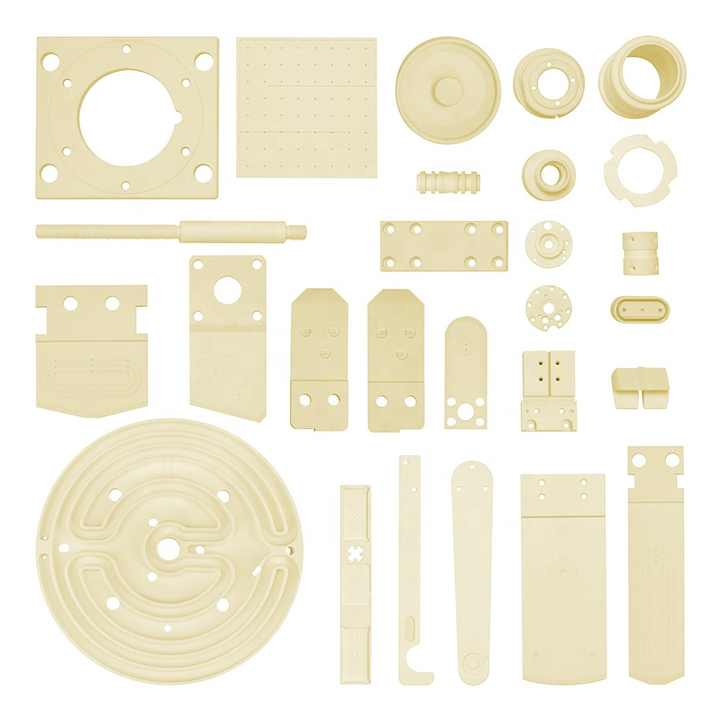

Industry Solutions

Hardware field: motor stator and rotor stamping dies, stretching dies, wear-resistant bushings

Electronic field: precision punching of heat dissipation holes for mobile phones/computers, micro connector molding molds

Medical equipment: High smoothness tungsten steel fittings, precision machining of ceramic components

Semiconductor lead frame processing: stamping and forming of precision components such as integrated circuit chip shells, pin connectors, packaging brackets, etc